Gages

Services & Solutions

Precision Gages: Ensuring Accurate Measurements Every Time

Precision manufacturing is essential to contemporary life everywhere, and nowhere is accuracy more critical than in the design and production of the instruments used to measure it.

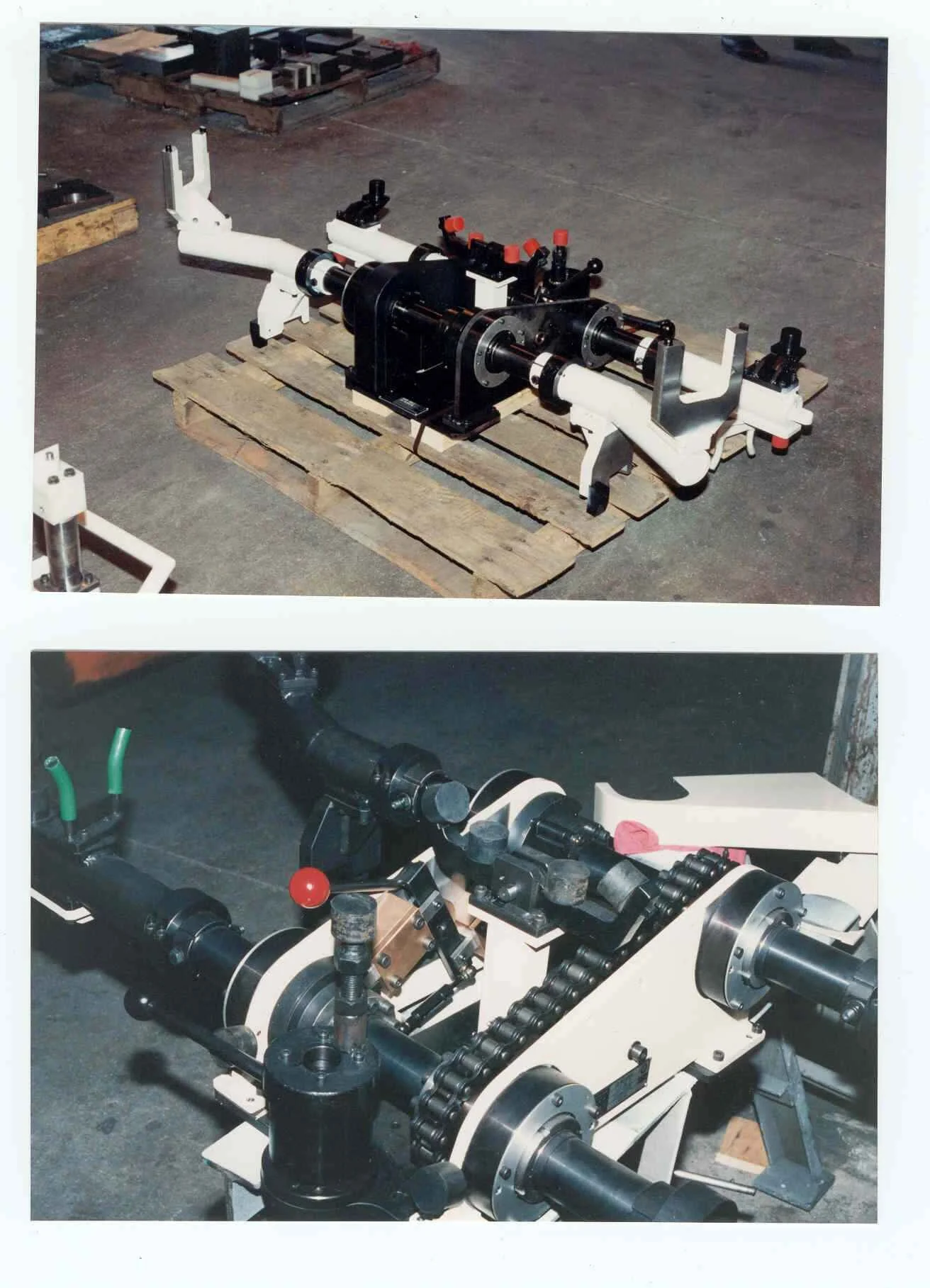

High-precision gages are a house specialty at Springfield Tool & Die. Our expertise lies in delivering measurement tools tailored to customers’ exact requirements. Impeccable quality control and consistent product performance help us set the standard for accuracy and reliability in gages.

Unparalleled Accuracy for Critical Applications

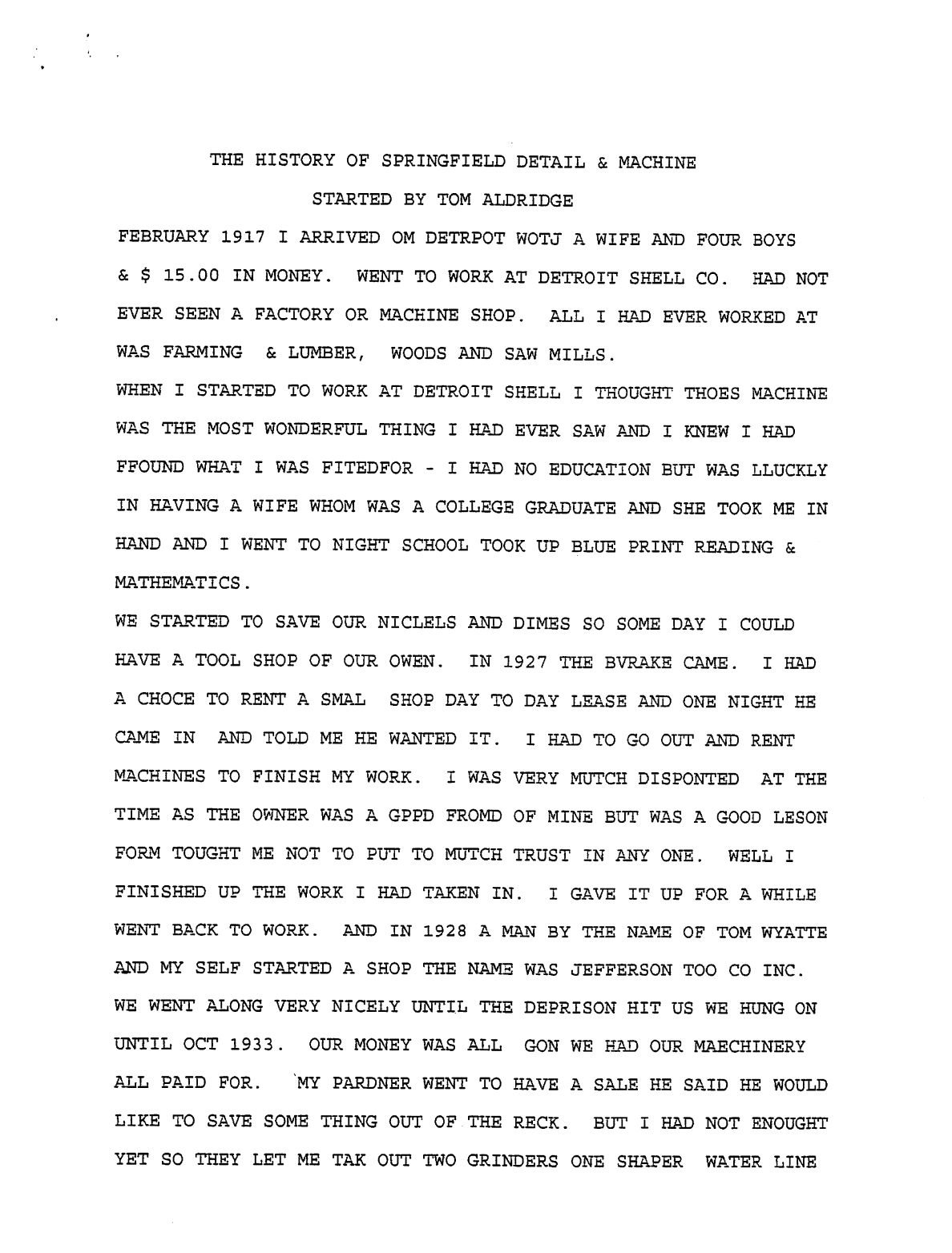

Precision is at the core of modern manufacturing, and our gages are crafted to meet even the most demanding tolerances. Whether for aerospace, automotive, medical devices, or general industrial production, Springfield’s gages ensure built components meet stringent quality standards. Our solutions include plug gages, ring gages, thread gages, and custom fixtures, all meticulously engineered to deliver consistent results in challenging environments.

Advanced Manufacturing Techniques

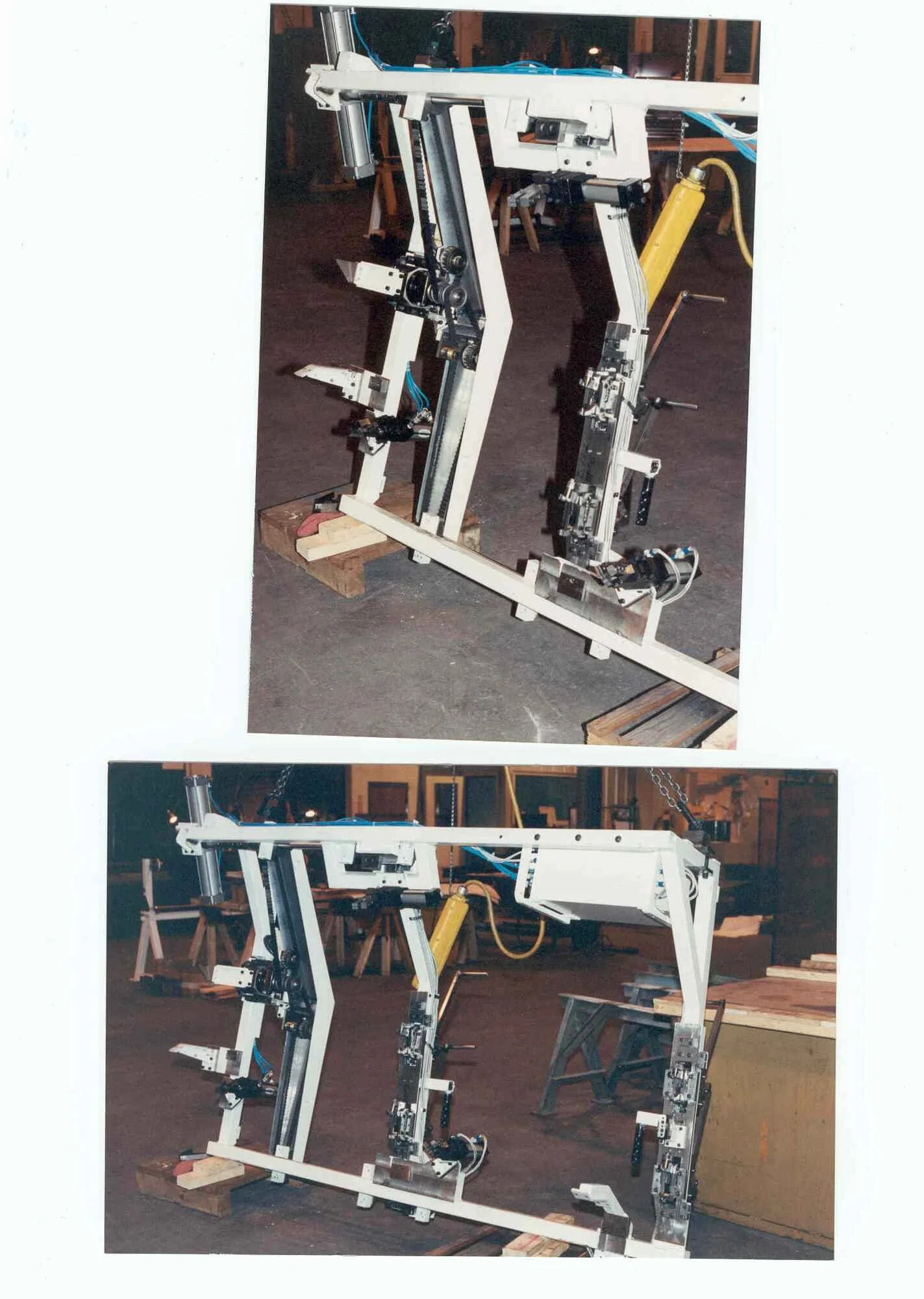

Our highly advanced facility is equipped with the latest in CNC machining, EDM, and grinding technology, enabling us to produce gages with exceptional detail and finish. Springfield Tool & Die's skilled technicians work with a variety of materials, including hardened steel, carbide, and specialty alloys, to ensure durability and long-term performance.

Customization to Suit Your Needs

No two manufacturing operations are alike, which is why we offer fully customized gaging solutions. Our team collaborates closely with you to understand your specific application requirements and design tools that integrate seamlessly into your processes. From concept to completion, we ensure every gage we deliver exceeds your expectations.

Rigorous Quality Assurance

Our highly advanced facility is equipped with the latest in CNC machining, EDM, and grinding technology, enabling us to produce gages with exceptional detail and finish. Springfield Tool & Die's skilled technicians work with a variety of materials, including hardened steel, carbide, and specialty alloys, to ensure durability and long-term performance.

Types of Gages We Use and/or Produce

There is no end to the variables that may come into play when designing and building an industrial gage. Springfield Tool & Die is adept at designing gages that are tailored to your specific requirements. Most are variations of these standard gages:

-

Go/No-Go Gages

Used to check whether parts meet specific dimensional tolerances.

Common for high-volume manufacturing applications where quick inspections are needed.

-

Plug Gages

Cylindrical tools used to check the diameter of holes or bores.

Often made in standard sizes or custom sizes for specific applications.

-

Ring Gages

Used to check the external diameters of parts.

Often employed in conjunction with plug gages for comprehensive inspection.

-

Thread Gages

Includes thread plug gages and thread ring gages for inspecting the accuracy of internal and external threads, respectively.

Can be made to standard thread profiles (e.g., UN, Metric) or custom specifications.

-

Height Gages

Used to measure vertical dimensions or the distance from a reference surface.

Common in precision machining and quality control.

-

Snap Gages

For inspecting external dimensions quickly, especially for high-volume parts.

Offers a quicker alternative to ring gages in some applications.

-

Fixture Gages

Custom-designed tools that integrate with inspection fixtures for complex parts.

Ensures parts fit properly in assemblies or match specific design criteria.

-

Custom Gages

Designed to meet unique customer needs, such as non-standard dimensions, shapes, or tolerances.